Hot-dipped galvanizing is the process of applying a thin layerof zinc directly on hot rolled or cold rolled steel coil by

passing it through a molten bath of zinc . Galvanizing steel forms a metallurgical bond between the zinc and the underly-

ing steel sheet . when exposed to the air, zinc reacts with oxygen , water , and carbon dioxide to form a layer of tough

zinc carbonate (ZnCO3 ). It protects the underlying steel and creates a barrier that becomes part of the steel itself and very

good formability.

MOQ:our moq should be 60mt per size

| Thickness | 0.13mm - 5.0mm |

| Width | 600mm - 1500mm |

| Zinc coating | 40g/m2 -500g/m2 |

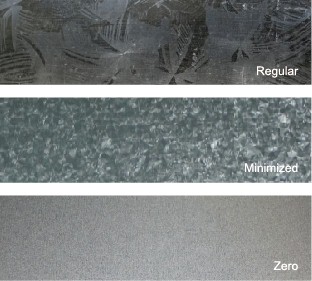

| Spangle | Regular / Minimized / Zero |

| Passivation | Chromated / Chromated-free |

| Surface Treatment | SKIN PASS |

| Oiled | Oiled / Dry |

| Coil ld | 508mm / 610mm |

| Coil weight | 3mt-18mt |

| Standard | JIS3302 | EN10327 / EN10326 | ASTM A653 |

| Grade | SGCC/SGCH | DX51D+Z / DX52D+Z | CS |

| SGC 340 | S22DGD+Z | SS GRADE 230 | |

| SGC 400 | S25DGD+Z | SS GRADE 255 | |

| SGC 440 | S28DGD+Z | SS GRADE 275 | |

| SGC 490 | S32DGD+Z | SS GRADE 340 | |

| SGC 570 | S35DGD+Z | SS GRADE 550 | |

| ; | S55DGD+Z | ; |

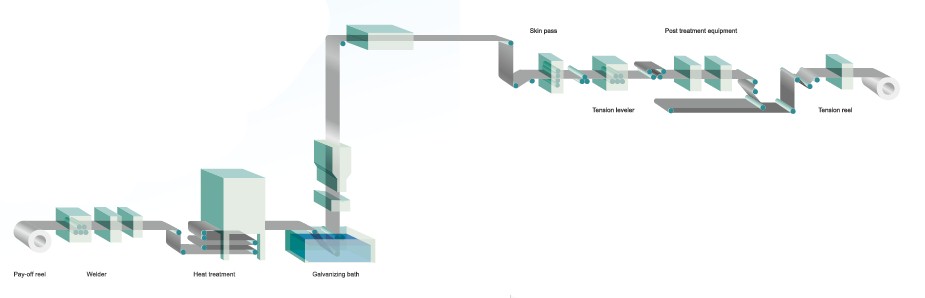

HOT-DIP GALVANIZING LINE

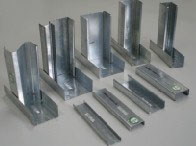

High corrosion, and rust resistance similar to that of

conventional chromate-treated sheet even with chromate

free treatment

Excellent zinc adhesion and responsiveness to severe

fabrication conditions .

MACHANICAL PROPERTY

JIS G 3302-1994

| Base Metal Classification | “Yield Strength(N/mm2)” | “Tensile Strength(N/mm2)” | % Elongation (Minimum) | |||

|---|---|---|---|---|---|---|

| Nominal Thickness (mm) | ||||||

| 0.25—0.40 | 0.60—0.60 | 0.60—1.00 | 1.00—1.50 | |||

| SGCC | -- | -- | -- | -- | -- | -- |

| SGCH | -- | -- | -- | -- | -- | -- |

| SCGD1 | -- | 270 min | -- | 34 | 36 | 37 |

| SGC 340 | 245 min | 340 min | (20)* | 20 | 20 | 20 |

| SGC 400 | 295 min | 400 min | (18)* | 18 | 18 | 18 |

| SGC 440 | 335 min | 440 min | (18)* | 18 | 18 | 18 |

| SGC 490 | 365 min | 490 min | (16)* | 16 | 16 | 16 |

| SGC 570 | 560 min | 570 min | -- | -- | -- | -- |

| Base Metal Classification | “Yield Strength (Mpa)” | “Tensile Strength (Mpa)” | %Elongation (Minimum) |

|---|---|---|---|

| “Applicable To full Range Of Nominal Thickness” | |||

| CS TYPE A | (170-380)* | -- | ≥20 |

| CS TYPE B | (205-380)* | -- | ≥20 |

| CS TYPE C | (170-410)* | -- | ≥15 |

| FS TYPE A & B | (170-310)* | ≥26 | |

| SS 230** | 230 min | 310 | ≥20 |

| SS 255** | 255 min | 360 | ≥18 |

| SS 275** | 275 min | 380 | ≥16 |

| SS 340** | 340 min | -- | -- |

| SS 550** | 550 min | 570 | ≥12 |

| Base Metal Classification | “Yield Strength(N/mm2)” | “Tensile Strength(N/mm2)” | % Elongation (Minimum) | |

|---|---|---|---|---|

| Nominal Thickness (mm) | ||||

| ≤0.70mm | 0.7mm-1.5mm | |||

| DX51D | -- | 270-550 | 20 | 22 |

| DX52D | 140-300 | 270-420 | 24 | 26 |

| S 220 GD | 220 min | 300 min | 18 | 20 |

| S 250 GD | 250 min | 330 min | 17 | 19 |

| S 280 GD | 280 min | 360 min | 16 | 18 |

| S 320 GD | 320 min | 390 min | 15 | 17 |

| S 350 GD | 350 min | 420 min | 14 | 16 |

| S 550 GD | 550 min | 560 min | -- | -- |

Back to top